Ukuguqula i-steelmaking calcium silicon Si40 Fe40 Ca10

Incazelo Yomkhiqizo

Ngemuva kokuthi i-silicon-calcium alloy i-deoxidized, ukufakwa okungezona okwensimbi okunezinhlayiya ezinkulu futhi kulula ukuntanta kuyakhiqizwa, futhi ukwakheka kanye nezakhiwo ze-non-metallic inclusions nazo ziyashintshwa. Ngakho-ke, i-silicon-calcium alloy isetshenziselwa ukukhiqiza insimbi ehlanzekile, insimbi yekhwalithi ephezulu enomoya-mpilo ophansi nesibabule, kanye nensimbi yokusebenza okukhethekile enomoya-mpilo ophansi kakhulu nesibabule. Ukwengezwa kwe-silicon-calcium alloy kungaqeda ukugoqa kwensimbi nge-aluminium njenge-deoxidizer yokugcina emlonyeni we-ladle, kanye nokuvala umlomo wombhobho we-tundish yokusakazwa okuqhubekayo | ukwenza insimbi. Kubuchwepheshe bokucwenga insimbi ngaphandle kwesithando somlilo, i-silicon-calcium powder noma ucingo oluyisisekelo lusetshenziselwa i-deoxidation kanye ne-desulfurization ukunciphisa okuqukethwe komoya-mpilo nesibabule ensimbi kuze kube sezingeni eliphansi kakhulu; ingakwazi futhi ukulawula uhlobo lwe-sulfide ensimbi futhi ithuthukise izinga lokusebenzisa i-calcium. Ekukhiqizeni i-cast iron, ngaphezu kwe-deoxidation nokuhlanzwa, i-silicon-calcium alloy nayo idlala indima ye-inoculating, esiza ukwakha i-graphite ehlanjululwe kahle noma eyindilinga; yenza i-graphite ngensimbi empunga isatshalaliswe ngokulinganayo, inciphisa ukuthambekela kokwenza mhlophe; futhi ingakhuphula i-silicon kanye ne-desulfurize, Thuthukisa ikhwalithi ye-cast iron.

Ukusetshenziswa

Njenge-compound deoxidizer (i-deoxidization, desulphurization and degassing) Isetshenziswa ekwenzeni insimbi, ukuncibilikisa ingxubevange. Njenge-inoculant, ibuye isetshenziswe ekukhiqizeni ukukhiqiza.

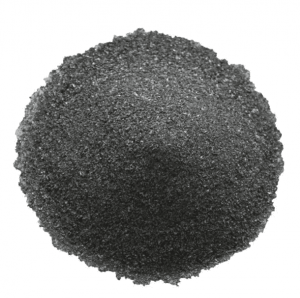

Isimo somzimba

ThIsigaba se-e ca-si simpunga ngokukhanyayo evele inomumo osobala wokusanhlamvu. Isigaxa, okusanhlamvu kanye nempushana.

Iphakheji:

inkampani yethu inganikela ngezimo ezihlukahlukene ezishiwo okusanhlamvu ngokuvumelana nezidingo zabasebenzisi, ezipakishwe ngendwangu yepulasitiki kanye nesikhwama sethani.

I-Chemical Element

| Ca | Si | Fe | AI | C | P |

| 10-15% | 40-45% | 40-45% | 2.0%ubuningi | 0.5%ubuningi | 0.05%ubukhulu |