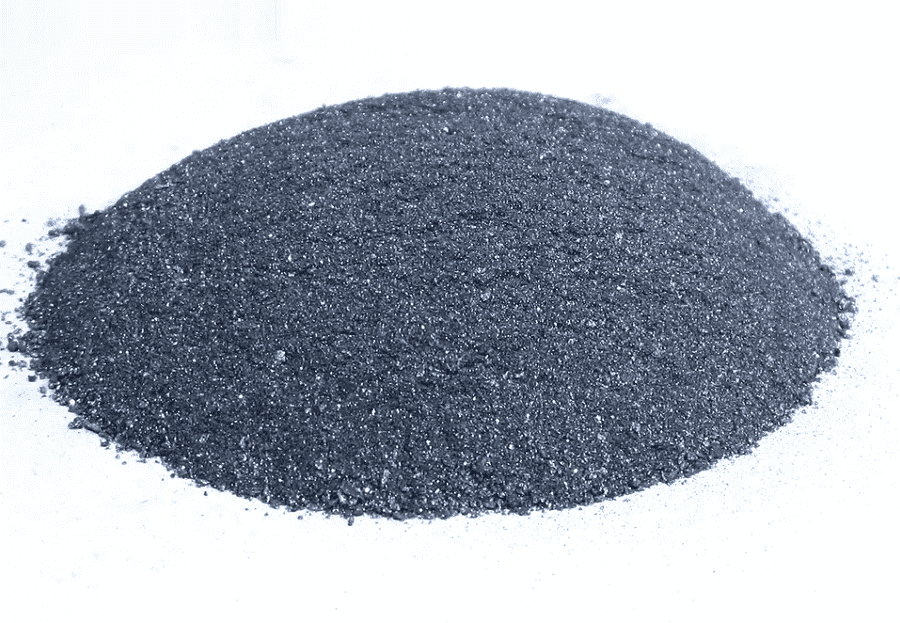

Izinhlayiyana Ezinhle Kakhulu ze-Ferro Silicon Yokusakaza

sebenzisa

(1) Izinhlayiya ze-Ferro silicon azikwazi ukusetshenziswa kuphela embonini yokwenza insimbi kodwa futhi njengento evame ukusetshenziswa njengensimbi embonini yensimbi ekhonjiwe. Lokhu kungenxa yokuthi izinhlayiya ze-ferro silicon zingasetshenziswa abakhiqizi bensimbi yokusansimbi ukuze bathathele indawo yokujova kanye nama-spheroidizer. Embonini ye-cast iron, intengo yezinhlayiya ze-ferro silicon iphansi kakhulu kuneyensimbi futhi zincibilika kalula, okuzenza zibe umkhiqizo ophezulu we-cast iron alloy. Ikhwalithi ephezulu ye-ferro silicon particle inoculant enosayizi wezinhlayiyana ezifanayo kanye nomthelela omuhle wokujova ngesikhathi sokuphonsa kungakhuthaza imvula ye-graphite kanye ne-spheroidization, ikwenze kube into edingekayo ye-metallurgical ukukhiqiza i-ductile iron.

(2) Isetshenziswa njenge-deoxidizer kanye ne-alloying embonini yokwenza insimbi. Ukuhlobana kwamakhemikhali phakathi kwe-silicon nomoya-mpilo kukhulu kakhulu, ngakho-ke izinhlayiya ze-ferro silicon zingama-deoxidizer aqinile ekwenzeni insimbi ukuze kube nemvula kanye ne-diffusion deoxidation. Embonini yokwenza insimbi, kuvame ukusetshenziswa njenge-ejenti yokushisisa i-ingot cap ukuze kuthuthukiswe ikhwalithi kanye nokutholakala kwe-ingot ngokusebenzisa isici sokuthi izinhlamvu ze-ferrosilicon zingakhulula ukushisa okukhulu ekushiseni kwe-ene ngezinga lokushisa eliphezulu.

Izinhlayiyana ze-Ferro Silicon zokukhiqiza insimbi engagqwali

1. Intengo ephansi futhi kulula ukuncibilika

izinhlayiya ze-ferro silicon azikwazi ukusetshenziswa kuphela embonini yokwenza insimbi kodwa futhi embonini yensimbi ekhonjiwe ngokuvamile isetshenziswa izinto zensimbi, ikakhulukazi ngoba izinhlayiya ze-ferro silicon zingasetshenziswa abakhiqizi bensimbi ekhonjiwe esikhundleni sama-inoculants nama-nodulators, embonini yensimbi ekhonjiwe, intengo. yezinhlayiya ze-ferro silicon iphansi kakhulu kunensimbi, futhi incibilika kalula, iwumkhiqizo we-ferroalloy onekhono lokuphonsa.

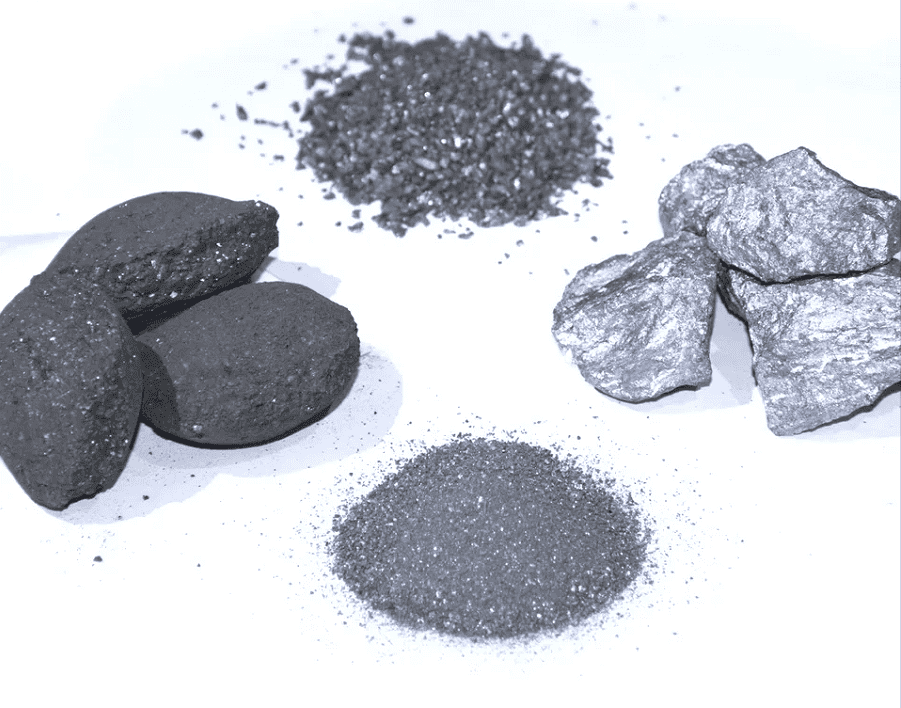

2. Usayizi wezinhlayiyana ezifanayo

Izinhlayiya ze-Ferro Silicon azinayo impushana enhle, umphumela ozinzile wokugoma, kanye nokuthambekela okuncane kokukhiqiza i-slag. Okunzima kakhulu ukuthi banezici zezinye izijovo futhi zinezindleko eziphansi.

3. Ukunwebeka okuhle kanye nepulasitiki

Ukunwebeka kwayo okuphansi kungenxa yokugoba kwayo okuphansi, futhi amandla ayo aqinile aphakeme ngokuphindwe kaningana kunalawo ensimbi evamile ethambile. Izinhlayiya ze-ferro silicon nazo zinokumelana nokugqwala okuhle kakhulu, futhi isendlalelo sayo esivikelayo singavimbela ngempumelelo ukugqwala okungaphezulu kokubunjwa.

4. Ukusebenza kahle

Izinhlayiya ze-Ferro silicon zinezakhiwo ezinhle zokucubungula imishini, zingaqeda ngokushesha imisebenzi yokucubungula eyinkimbinkimbi, futhi zibe nokuzinza okuhle nokumelana nokugqoka, kanye nempilo ende yesevisi. Okusho ukuthi, izinhlayiya ze-ferro silicon zinezakhiwo ezinhle zemishini kanye nezindawo ezisele ezicishe zibe yi-zero, ezizenza zibe izinto ezikahle zokuphonsa embonini yokuphonsa.

5. Izakhiwo ezinhle kakhulu ze-thermoplastic

Izinhlayiya ze-Ferro silicon zinezinto ezinhle kakhulu ze-thermoplastic, zingamelana nokuguquka ngaphansi kwezimo ezihlukahlukene zokushisa okuphezulu, futhi zingagcina amandla azo emazingeni okushisa aphakeme, zizenze zifaneleke ikakhulukazi ukusetshenziswa ekukhiqizeni ama-thermoplastic castings.

Isici samakhemikhali

| Into% | Si | P | S | C | AI |

| ≤ | |||||

| FeSi75 | 75 | 0.03 | 0.02 | 0.15 | 1 |

| FeSi75 | 75 | 0.03 | 0.02 | 0.15 | 0.5 |

| FeSi75 | 75 | 0.03 | 0.02 | 0.1 | 0.1 |

| FeSi75 | 75 | 0.03 | 0.02 | 0.05 | 0.05 |

| FeSi75 | 75 | 0.03 | 0.02 | 0.02 | 0.02 |

| FeSi72 | 72 | 0.03 | 0.02 | 0.15 | 1 |

| FeSi72 | 72 | 0.03 | 0.02 | 0.15 | 0.5 |

Qaphela: Ukukhiqizwa kokucaciswa okuhlukile kwe-silicon calcium alloy ngokuya ngezidingo zamakhasimende